Bespoke furniture and manufacturing from biobased material

Growmolding allows designers and manufacturers to tailor 100% biodegradable components with intricate, custom designs.

Our semi-industrial biocomposite manufacturing process enables the creation of bespoke shapes and provides a sustainable alternative to a range of materials including expanded polystyrene (EPS), expanded polypropylene (EPP) and molded polyurethane foams. With our dedicated furniture-focused manufacturing we can produce large parts with complex shapes.

Bio-based, zero waste & 100% compostable

Our company name Growmolding is derived from our manufacturing process, where active mycelium strains act like a binder that grows hemp fibre into a strong bio-composite. We grow this composite inside molds.

This bio-composite is called MBC (Mycelium Based Composite). Our raw material consists of 90% locally grown hemp fiber and 10% binder material. After the production cycle, the composite becomes a fully inert material that is stable, strong, and durable.

Growmolding is making progress towards CO2 negative* products to help you reduce your carbon footprint and meet ESG targets.

MBC is not just bio-degredable; it`s 100% compostable by nature.

The wood part of the hemp plant used in our material is an agricultural by-product. The hemp comes from local European crops and is converted into custom molded parts in our factory in Enkhuizen, the Netherlands.

The exact amount of raw material required to produce the part is used to fill the mold, resulting in hardly any post-consumer waste.

We work with and inspire other innovative eco-entrepreneurs who are developing sustainable materials to create finished products such as bio-foam fillings, durable textiles, and smart upholstery methods. We also work with partners to develop adhesives, sealants, coatings, and finishes that can be applied to MBC. We call this our Eco Chain.

Custom molded parts for the (furniture) industry

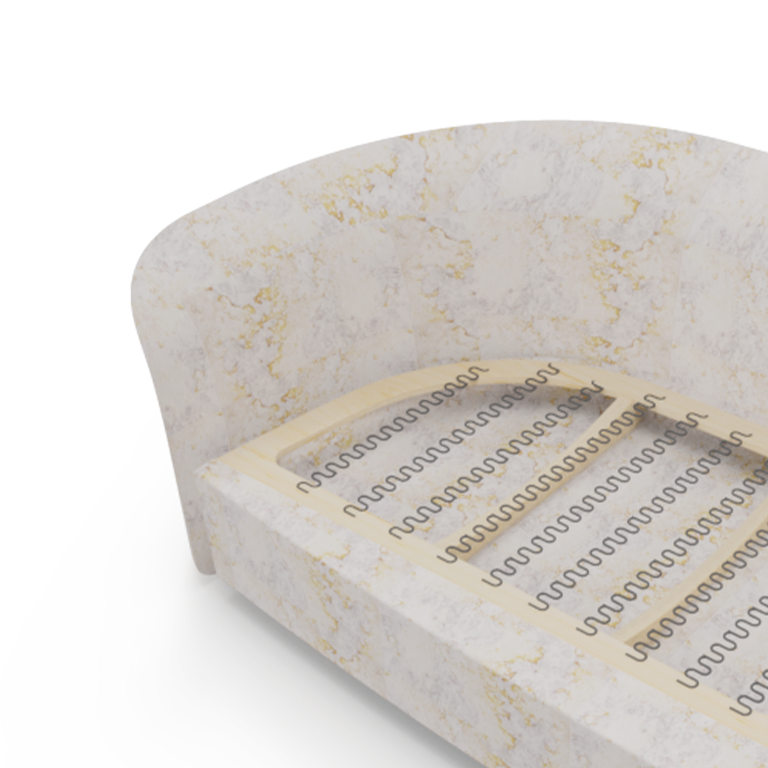

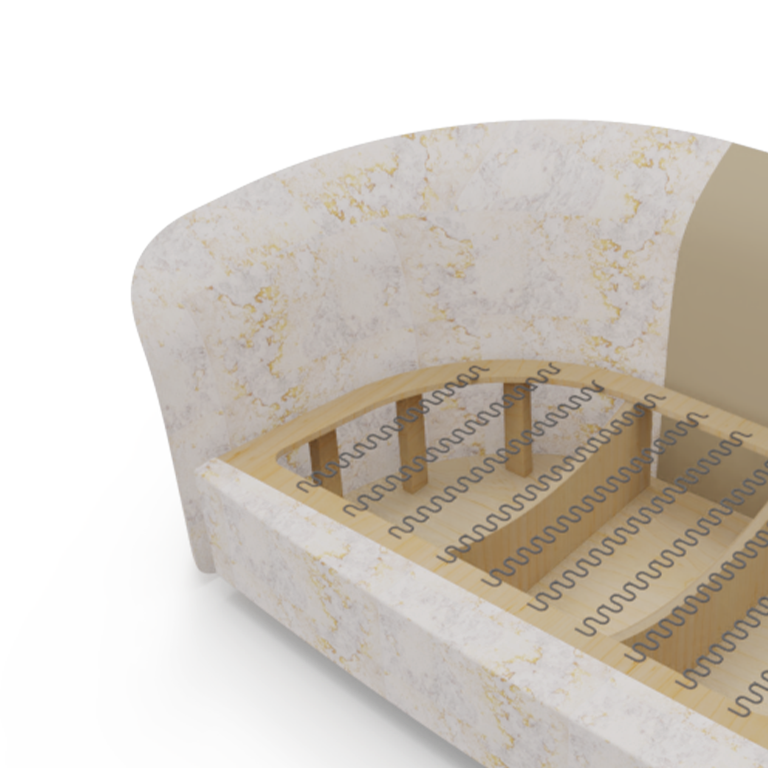

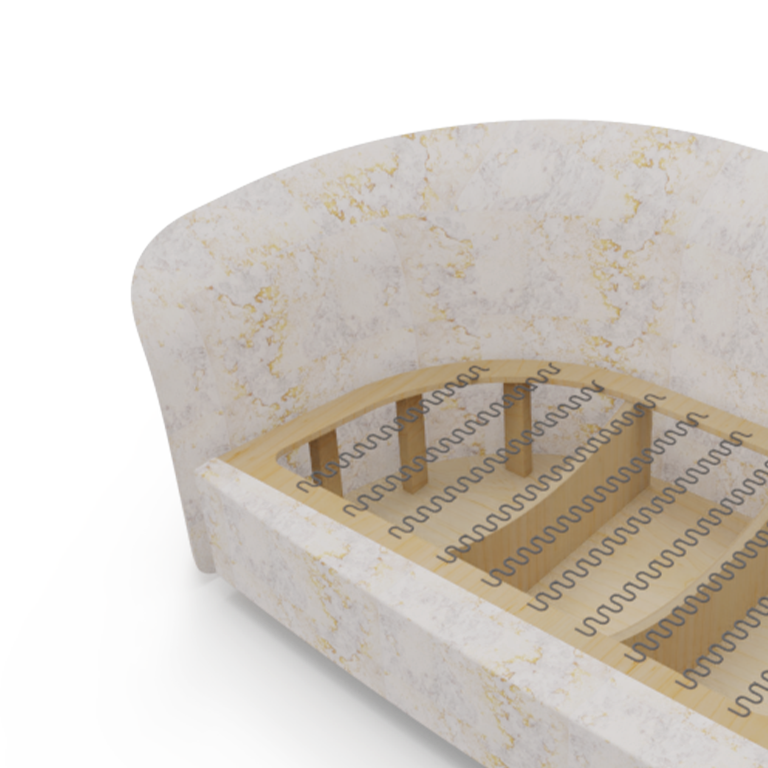

Recognising the need for sustainable solutions for the furniture industry, Growmolding was founded by furniture industry experts. The structural properties of hemp-based MBC allow it to grow naturally compostable, mono-material furniture hulls that replaces non-recyclable alternatives such as molded polyurethane foam.

Highlights

Our focus is on structural (technical) parts used as a base for upholstered products. Through our experience and knowledge of both moulding and manufacturing, we have developed methods that offer unexpected possibilities and solutions to achieve complex shapes and well defined details.

MBC parts can also serve as structures to be finished with materials such as wood veneer, coatings, ceramic tiles or other surface materials to create small furniture or accessories.

Our semi-industrial process allows us to produce custom molded parts with almost unlimited freedom of design. This can include undercuts, post-molded additions, integrated fasteners and so on.

Our process allows for molds that are affordable and adaptable. For most applications, the molds can be recycled into molds for new products should they become obsolete.

Growmolding is very competitively priced for complex designs combined with relatively low annual volumes.

The price per part is highly competitive with fossil alternatives, especially when we co-develop your project to make it as economical as possible!

The minimum order quantity is 1 (one!) item per order. However, larger quantities are more efficient to produce and will result in better prices. A single mold can produce up to 70 parts per year.

Mycelium forms a thermal protective char when exposed to radiant heat. Hemp based MBC is rated similar to most woods and much better than PU, EPS and other fossil based plastics or composites, without any toxic additives.

Sustainable, customised design in small series and with low investment costs.

Our complementary services include coverings, assembly and packaging.

Growmolding is committed to providing the best possible service to support our customers in the furniture industry and beyond. We actively maintain and research complementary sustainable materials and processes in our supply chain to complement our MBC parts. We can offer finished upholstered products by developing your product to be complemented with filling materials and high quality upholstery.

Our in-house design engineers will help you realise the most effective design solutions for your product.

You're welcome.

We are eager to hear your ideas and, over a fresh cup of coffee or tea, give you feedback on technical and commercial compatibility with our process.